”The plastic bomb” has exploded in the media in a major way. Everyone of us has heard about, for instance, giant plastic islands floating in the oceans that just keep getting bigger. It is clear that new, more responsible rules are needed for manufacture and use of plastics.

It’s a big problem that plastic tends to be something you use only once. According to estimates, only 5% of the value of plastic packaging material retains in the economy, the rest is lost after a very short first-use. In the EU, less than 30% of plastic waste is collected for recycling. The usage rate of recycled plastic accounts only for 6% of the total demand for plastic.

There is nothing, however, to stop us from building processes that facilitate better recycling for plastics.

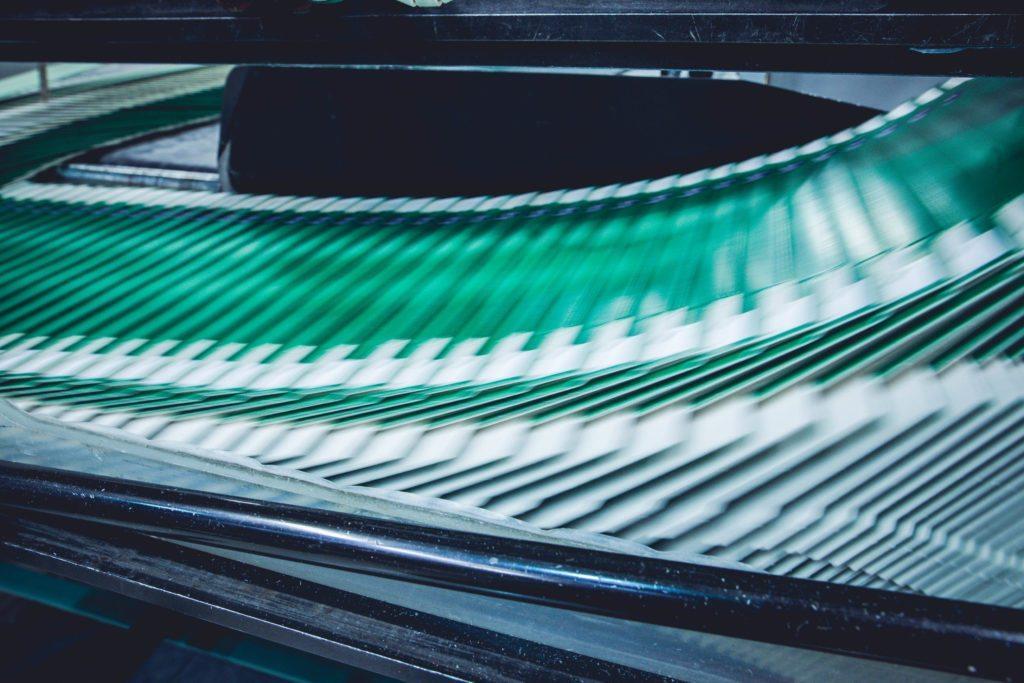

Pyroll Merikarvia (SeaPack Oy) manufactures plastic bags by utilising used plastics. About 70-80% of our raw material is collected recycled plastic from industry and consumers. Annually, tens of millions of plastic bags are made at Merikarvia.

Pyroll Merikarvia has manufactured plastic bags since the early 1980’s, so there is plenty of expertise and experience in the unit. In recent years, the operations have been finetuned in order to better adapt to the principles of Circular Economy. The plant has, for instance, its own granulation line which makes it possible to immediately utilise left-over materials from production.

Still, Circular Economy doesn’t have to be about big machinery investments. It can also be – and it should also be – about using the existing machines in smarter ways, more sustainably and responsibly. By developing the process ever onwards, we have achieved great results – and we aim to stay on this path, too.

The EU has taken note of the plastic crisis as well and issued its first ever plastics strategy in January 2018. The strategy wants to transform the way products are designed, produced, used, and recycled in the EU. The goal is to protect the environment while at the same time laying foundations to a new plastic economy, where the design and production fully respect reuse, repair and recycling needs and more sustainable materials are developed.

In addition, new rules on packaging will be developed to improve the recyclability of plastics used on the market and increase the demand for recycled plastic content. With more plastic being collected, the EU wants to set up improved and scaled up recycling facilities, alongside a better and standardised system for the separate collection and sorting of waste across the EU. The EU Commission finds that these changes will deliver greater added value for a more competitive, resilient plastics industry.

The EU is clearly doing the right thing. Industrial players should always be evaluating their processes with a critical eye – and strive for sustainability. Plastic is but one factor of the equation – but it’s a factor that has great significance for the people as well as the planet.

Juppe Suhonen

Merikarvia (SeaPack) Plant Manager